NOTCam Cooling

If the PTR has stopped

If the PTR has stopped when it is supposed to be running and NOTCam is

supposed to be kept cold, then:

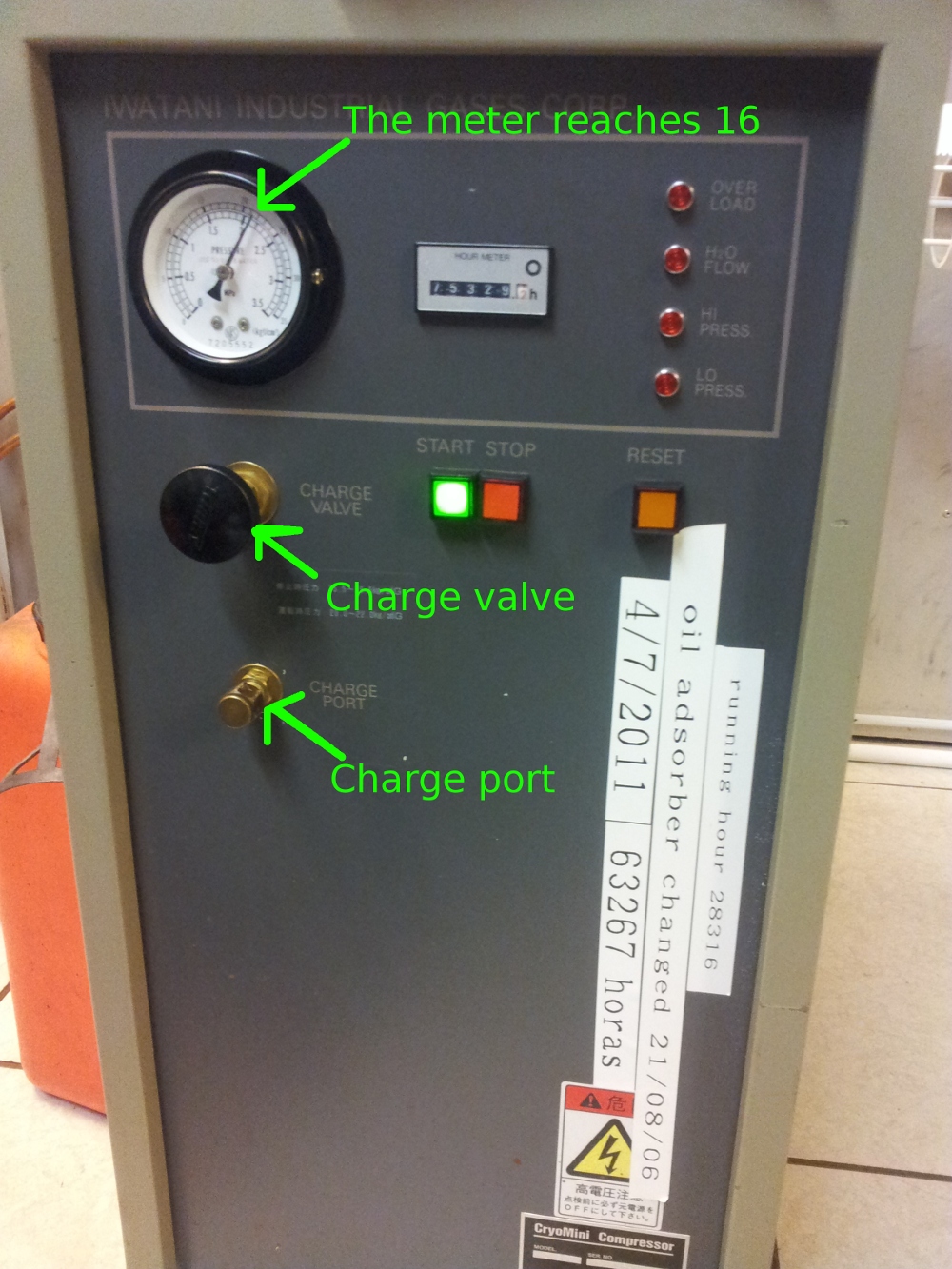

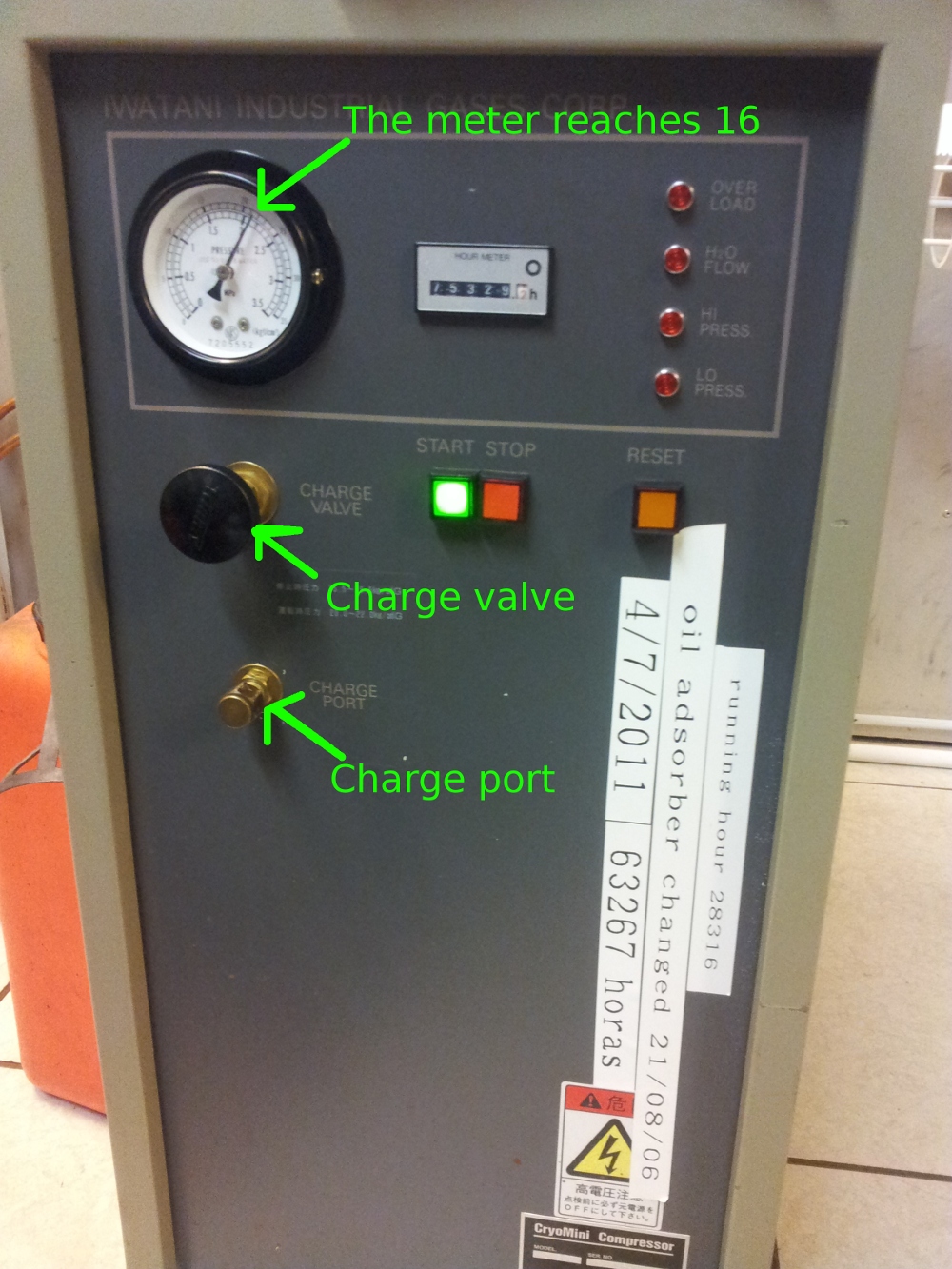

- Go to the PTR compressor in the machine room and check what is the

error message out of the four possible: "H2O flow", "LO PRESS",

"HI PRESS", or "Overload", indicated by a red light at the upper right

of the compressor front panel.

- If the error is "H2O flow" then the cooling water is outside the

allowed range of 10-30 degree Celsius. First try to get air bubbles out of

the system by opening the PURG-O-MAT air-escape valve for a few seconds,

perhaps also knock or shake it a bit. If this did

not help, then see description on how to adjust the water flow under

points 4 - 8 below under Special PTR Instructions

- If the error is "LO PRESS" this means there is too little Helium in

the system. See the instructions for

Filling the PTR with He.

- In order to reset the compressor press first the reset button.

- Now you can try to re-start it again, by pressing the green Start

button. Be aware that it takes up to a minute before the PTR starts to

run fully. Wait at least 10 minutes to restart after

the compressor has stopped otherwise the lifetime of the system

will be shortened.

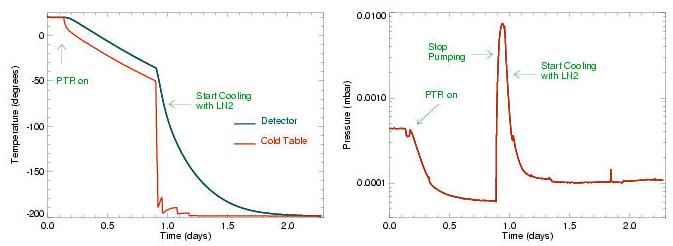

Instructions for cooling NOTCam down from a warm state.

In all normal conditions we use the PTR to bring the dewar temperature

down as far as possible before filling with LN2. With the PTR alone it

takes about 18 hours to bring NOTCam down from +15 to about -50 degrees.

Therefore, it is recommended to start the PTR in the afternoon, at the

latest, such that LN2 cooling can start the next morning.

NB! The array controller should be turned OFF during

cool down!

Only in exceptional cases should LN2 be filled directly into a warm

vessel in order to save time. According to our experience the cooling

rate is at most 0.8 K per minute when filling "aggressively" with LN2.

Note that the requirement from Rockwell is that the cooling rate

is less than 1 K per minute.

When the vacuum pressure is below 10-2 mBar, it is safe to start

cooling. If 10-2 mBar is not achieved within 24 hours, there might

be a leak. In June 2001 we reached 5.3 ×10-3 mBar in 48 hours.

Normally the PTR is connected and

ready, and you can skip the following steps under Special PTR

instructions.

Follow instructions from section Starting the

PTR.

Special PTR instructions

The PTR (or CryoMini) manual is found in the right cupboard

on the observing floor together with the PTR tools.

- Check that the PTR rotary valve has been connected correctly to NOTCam.

This is usually done as part of the transport-to-dome procedure. If

not, then follow the instructions in the CryoMini manual. Look at

the drawing, and use the proper PTR tools. Place the

tube vertical in line with the mounting piece, and turn the knob by

hand as long as it goes easy, while holding it straight. Then use the

tools and tighten quickly (in order to minimize helium leakage) until

fully connected.

- Check that there is power on the compressor, which is in the machine

room on the floor and next to the door from the entrance hall.

If there is no illuminated red light on the front of the compressor

then go in to the electronics room (sometimes referred to as the filter

room) and at the switchboard (where the two keys are for the telescope

power), behind door 2H, turn on the compressor using the switch labelled

NOTCAM PTR (up is on). Also check that the earth leakage breaker next

to it is on (up).

- You should not need to do this, but check that the pink coloured cooling

water pump, mounted on the wall behind the compressor, is running, it

will be vibrating slightly if it is on. If the pump is not running you

probably only need to plug it into the mains behind the compressor.

Connect the cable with the switch

off, then switch power on. Now you have recirculation to the cooler on

the dome floor.

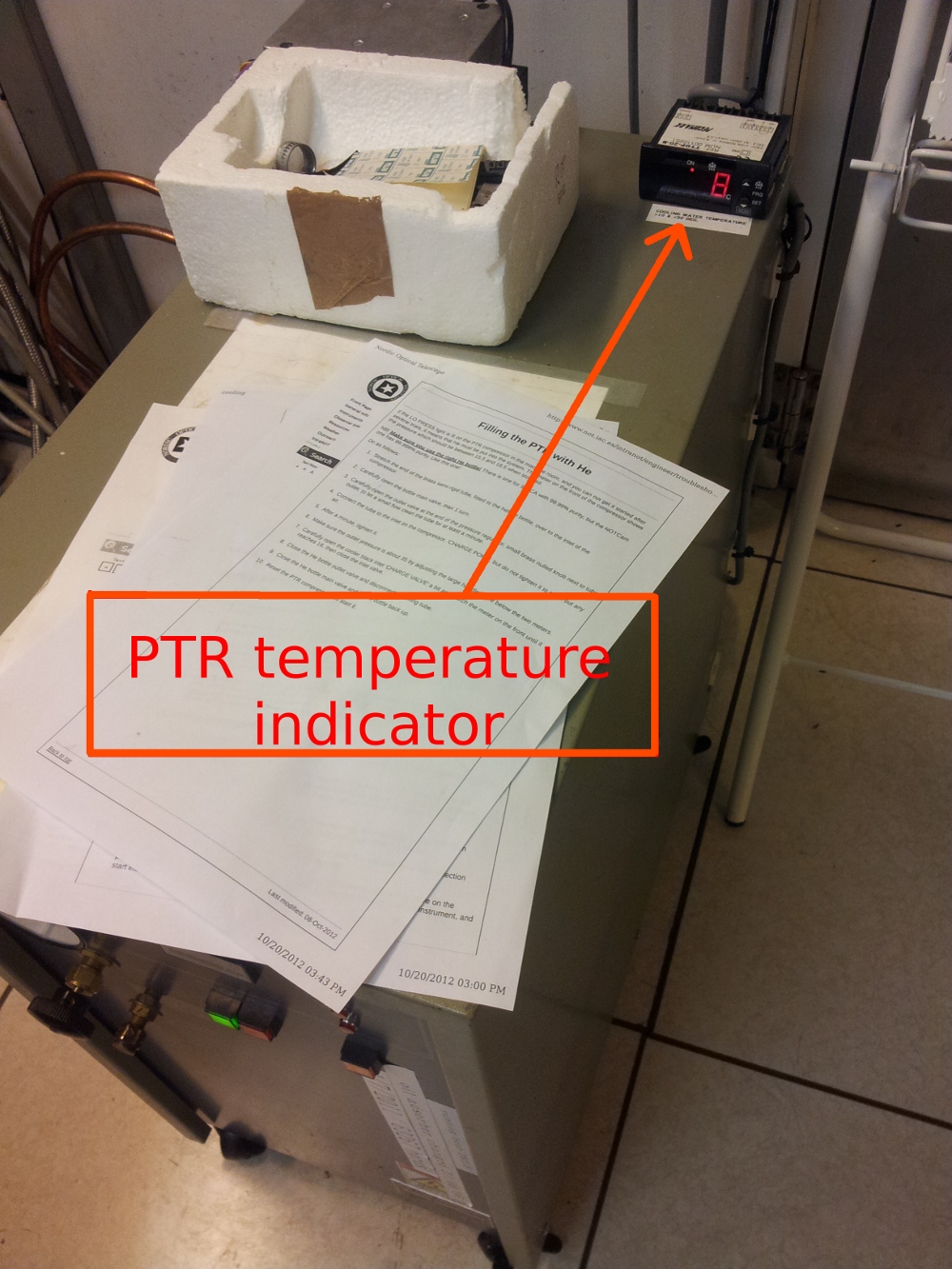

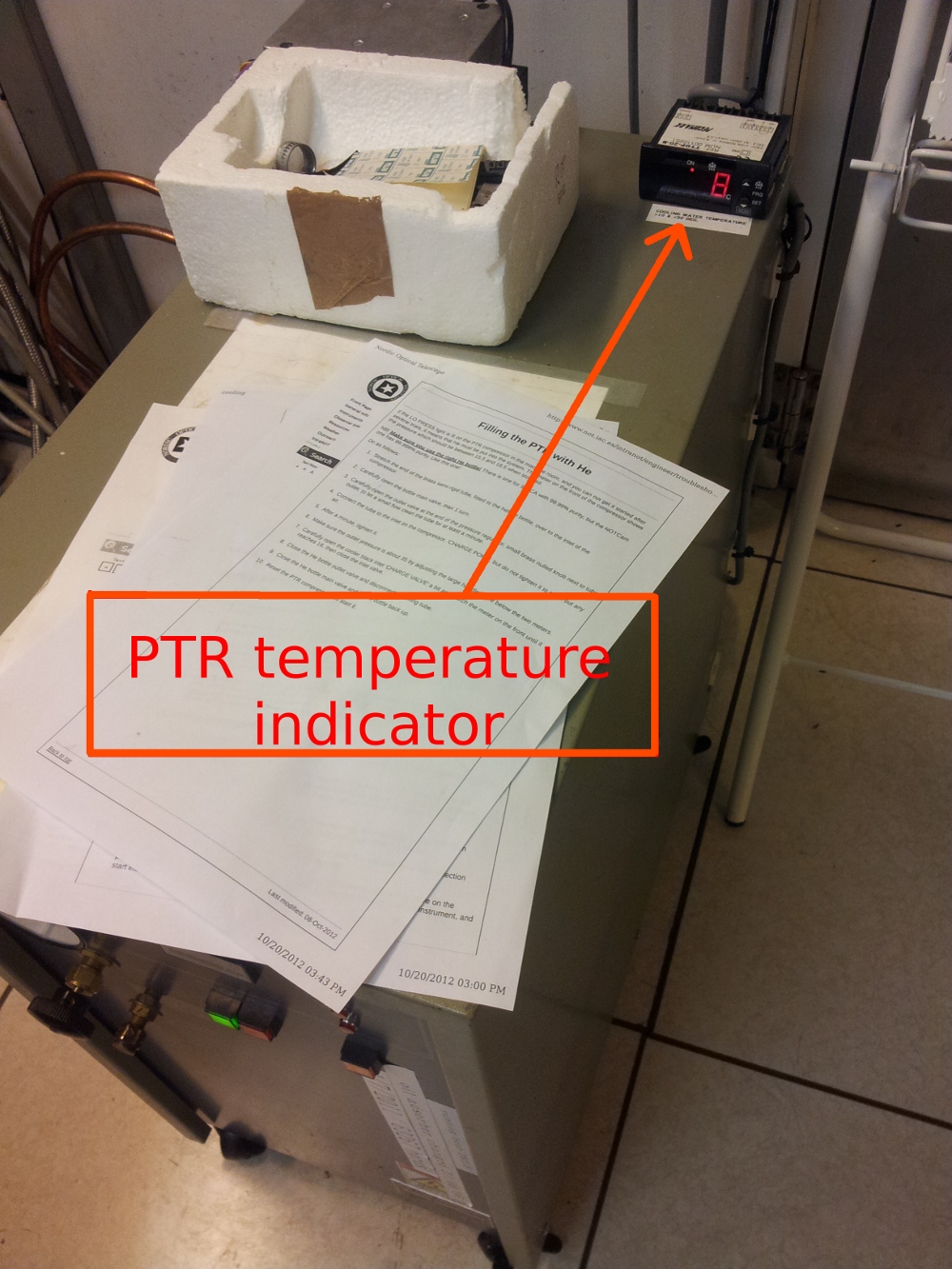

- The temperature of the cooling water is shown on

the digital display mounted on top of the PTR compressor. When the

PTR is running, the water temperature should be between 10 and 30

degrees.

If the PTR is not running it is normally below 10 degrees, but it should

quickly rise as soon as the PTR is switched on.

- The PTR is turned on by pressing the green button on the front panel

of the compressor. If the PTR has stopped because of some error, a red

lamp

on the front panel will indicate which error caused it to stop. You have

to press "reset" before you try to turn on the PTR again.

- If after a minute or so the compressor turns itself

off with the "LO PRESS" lamp illuminated then you need to fill the PTR

with helium by following the Filling PTR with He

instructions.

- If the displayed temperature stays out of range, or if the PTR stops

with the "H2O flow" lamp illuminated, then there are

problems with the water flow. Try first to get rid of possible air

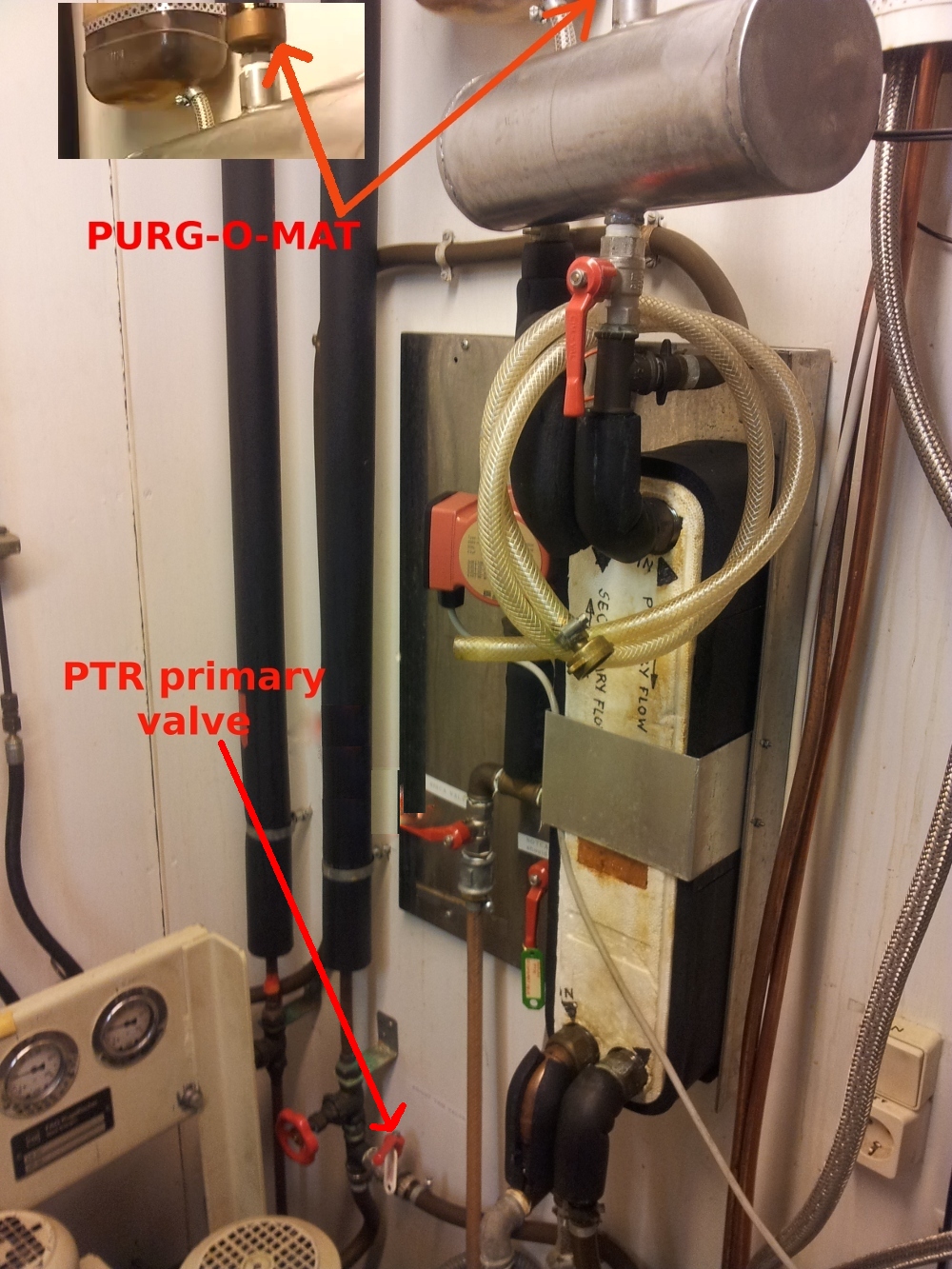

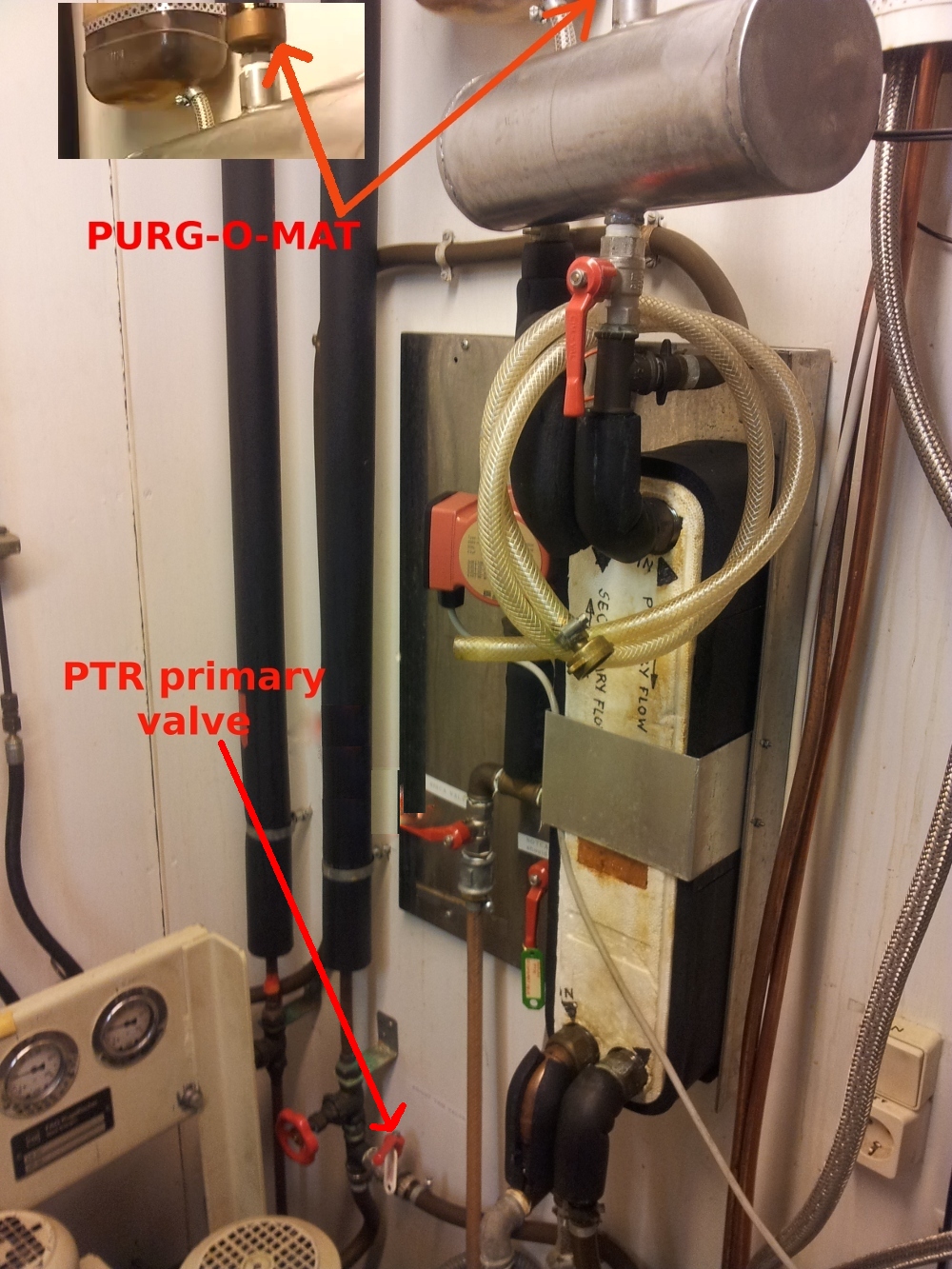

bubbles by opening the PURG-O-MAT air-escape valve for a few seconds

until water comes out. If no air came out and this did not help, you

you may need to adjust the PTR water cooling valves. There are two

red valves called

PTR primary and PTR secondary, located on the wall to the

left of the compressor, behind the hydraulics.

Don't touch the one labelled SIRCA! The PTR secondary valve

should always be fully open. The PTR primary valve is usually

only open by just 10 degrees from closed position. (It is closed when

it is at right angles to the tube.) This is

the one to adjust. If you want to increase the temperature it should be

more closed, and if you want to decrease the temperature it should be

opened a bit. Only small movements (of the order of 5 degrees or so)!

Check the temperature of the inlet water on the digital display mounted

on top of the PTR compressor a few minutes after adjustment. Keep it

between 10 and 30 degrees.

- Keep track of the temperature for several hours. Adjust it by turning

the PTR primary valve which regulates the flow of cooling water. NB!

Small movements.

Starting the PTR to cool NOTCam from warm state

- Make sure the array controller is turned off.

- Let NOTCam continue to pump. (Leave the pump running until the moment

you start filling NOTCam with LN2.)

- Turn on the PTR by pressing the green button on the front panel of

the compressor (located in the machine room). Usually the PTR is

running for 18-24 hours before filling with LN2.

- Keep track of the cooling water temperature for a while. You can read it

on the digital display on top of the compressor. It can also be

monitored from the

NOT Thermal Monitoring system, where you select sensor 367. The

cooling water should be between 10 and 30 degrees. If it is not, then

check the Special PTR instructions above.

- If this is the start-up of NOTCam cooling after an opening, then

the email warning system about the PTR coolant temperature has been

stopped and must be restarted. This is done from the

TMS Alert Control web interface where you activate sensor 367 with

min = 10.00 and max = 30.00 to be checked hourly and recipients=dstaff.

Make sure the information to follow the email text is correct.

Continue cooling NOTCam from warm state with LN2

When using liquid nitrogen (LN2) always wear the provided gloves, full face

mask, proper shoes (not open toe sandals) and apron!

- NB! Even if the PTR has been running for 18-24 hours first, it will take

at least 40 hours from the moment LN2 is filled for the first time until

the detector reaches operating temperature (with proper refillings).

Always start the LN2 filling at the latest 2 days before the day/night

when NOTCam is scheduled for use.

- NB! LN2 filling is something you should start doing in the morning. You

will need to refill NOTCam several times during the day (typically

within 1-2 hours and then again after 7-8 hours).

- NB! Let the vacuum pump keep pumping during the first stages of filling!

- To stop pumping do the following: close the vacuum valve to the

instrument, then the valve on the pump.

Verify that both are closed, and turn off the pump. Disconnect the pump

from the instrument, and start immediately to fill with LN2.

When filling with LN2, open one of the dome side ports a small amount

to ensure adequate ventilation. If the dewar is cooled from room

temperature with LN2 then a large volume of gaseous nitrogen is vented

into the dome in a short time and may displace sufficient oxygen to

kill you!

- Use the NOTCam filling nozzle (the wide and short one) connected to

the LN2 bottle. Pull out the "cork" plugged into the NOTCam fill tube

and insert the filling nozzle. Clamp it with the right-angle

metal clamp attached to the structure. Open the valve slowly.

- There should not be any leaking/dripping of LN2 while filling. There

will be a loud whistling sound. Use the ear protection. You will notice

that

NOTCam starts to become full when this sound disappears, and right

after LN2 will pour out on the floor. Close the valve immediately.

Remove the LN2 bottle,

and close the fill tube with its cork. Note that the cork should be

introduced only so far that the first black o-ring is inside.

- Check the temperature logging.

You can do this from the web page

NOT Thermal Monitoring System where you select the sensors 500,

502 and 503. Alternatively, use any computer and login on marissa

as obs. Then type tail -f /home/software/notcam/NOTCAM_temp.

Each five minutes four different temperatures

and the pressure is updated. The first temperature is the cold table, the

next is the outer vessel (typically reflecting the dome temperature), the

third is the center wheel section, and the forth is the array temperature.

The last value is the pressure in mbar.

Mon Apr 7 10:17:47 2003 1049707067 -201.60 3.80 -197.30 -196.30 4.16e-05

- When NOTCam has reached below -190.0 degrees (detector), then start

the automatic TMS email alerts. This is done from the web interface

TMS Alert Control where you set min=-205, max=-195, frequency=hourly

and recipients=dstaff. Check that the text to go with the email is OK.

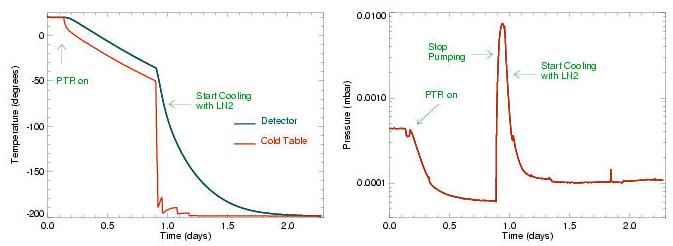

Example of temperature and pressure during cooling

|